Additive Manufacturing Market Projected to Reach USD 89.91 Billion by 2030

Rapid Technological Advancements and Growing Prototyping Demand Drive Market Expansion

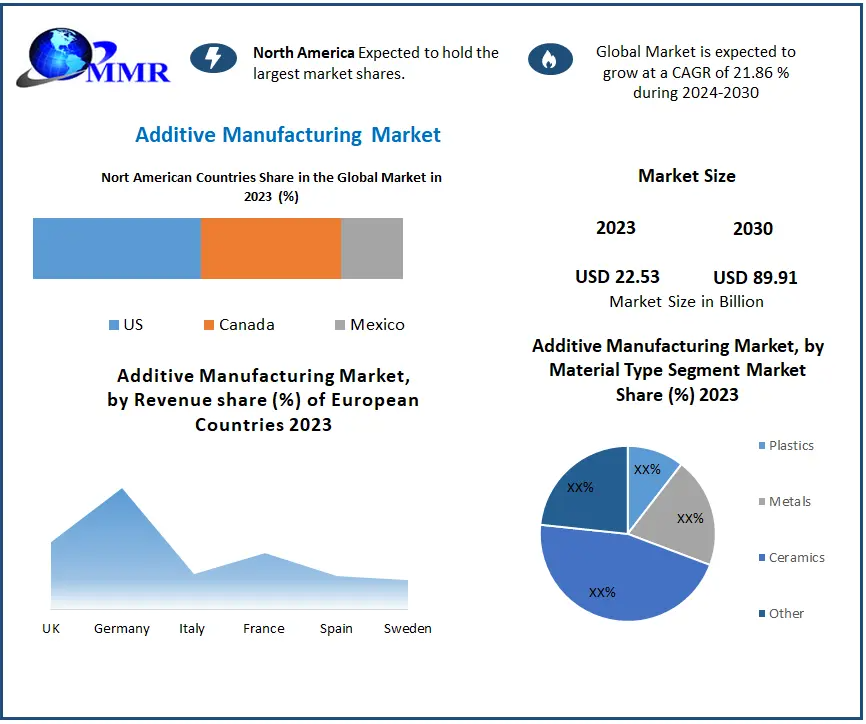

The Additive Manufacturing Market Share valued at USD 22.53 billion in 2023, is anticipated to experience a significant growth trajectory, reaching approximately USD 89.91 billion by 2030. This represents a compound annual growth rate (CAGR) of 21.86% during the forecast period from 2024 to 2030.

To learn more about the findings of this research, please check:https://www.maximizemarketresearch.com/request-sample/146140/

Market Definition and Overview

Additive manufacturing, commonly known as 3D printing, is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems. Unlike traditional manufacturing methods that often involve subtracting material from a larger piece, additive manufacturing builds objects layer by layer from a digital 3D model. This process offers unparalleled design flexibility and material efficiency, making it applicable across various industries, including aerospace, automotive, healthcare, and consumer goods.

Market Growth Drivers and Opportunities

Several key factors are propelling the growth of the additive manufacturing market:

-

Increasing Demand for Prototyping Across Industries: Sectors such as healthcare, automotive, and aerospace are increasingly adopting additive manufacturing for rapid prototyping. This technology accelerates product development cycles, allowing for quicker iterations and reduced time-to-market.

-

Technological Advancements: Continuous innovations in additive manufacturing technologies have enhanced the precision, speed, and material range of 3D printers. These advancements are expanding the applications of additive manufacturing, making it more accessible and cost-effective for various industries.

-

Expansion of 3D Printer Shipments: The global shipment of 3D printers has seen substantial growth, with 2.2 million units shipped in 2021. Projections indicate a surge to 21.5 million units by 2030, reflecting the increasing adoption of additive manufacturing technologies worldwide.

-

Government Initiatives and Investments: Governments across various regions are investing in additive manufacturing technologies to bolster industrial growth and innovation. These initiatives are fostering research and development activities, further driving market expansion.

For additional insights into this study, please refer to:https://www.maximizemarketresearch.com/request-sample/146140/

Segmentation Analysis

The additive manufacturing market is segmented based on technology, material, application, and region.

-

By Technology:

- Stereolithography (SLA): Utilizes photopolymerization to create parts with high resolution and accuracy.

- Fused Deposition Modeling (FDM): Employs thermoplastic materials to build parts layer by layer, widely used for prototyping and educational purposes.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered material, suitable for complex geometries and functional prototypes.

- Direct Metal Laser Sintering (DMLS): Involves melting and fusing metallic powders with a laser, ideal for producing metal parts with intricate designs.

- Others: Including Electron Beam Melting (EBM), Laminated Object Manufacturing (LOM), and more.

-

By Material:

- Polymers: The most commonly used materials in additive manufacturing, offering versatility and ease of use.

- Metals: Used for applications requiring high strength and durability, prevalent in aerospace and automotive industries.

- Ceramics: Applied in industries like healthcare for biocompatible implants and dental applications.

- Others: Including composites and bio-materials.

-

By Application:

- Prototyping: Dominates the market due to the technology's ability to quickly produce models for design validation.

- Tooling: Utilized for creating custom tools and fixtures, reducing lead times and costs.

- Functional Parts Manufacturing: Increasingly used for producing end-use parts, especially in low-volume, high-complexity scenarios.

Excited to dive in? Request your sample copy of the report to uncover its contents:https://www.maximizemarketresearch.com/request-sample/146140/

Regional Insights

-

North America: Currently leads the additive manufacturing market, driven by significant investments in research and development, along with the presence of key industry players. The region's strong focus on technological innovation and early adoption across various sectors contribute to its dominant position.

-

Asia-Pacific: Emerging as a rapidly growing market, propelled by government initiatives supporting industrial modernization and the adoption of advanced manufacturing technologies. Countries like China and Japan are at the forefront, leveraging additive manufacturing to enhance production capabilities and maintain competitive advantage.

Seeking a thorough market understanding? Dive into the summary of the research report:https://www.maximizemarketresearch.com/market-report/additive-manufacturing-market/146140/

Competitive Landscape

The additive manufacturing market is characterized by a dynamic competitive environment, with key players focusing on innovation, strategic partnerships, and expanding their product portfolios. Notable companies in the market include:

-

Stratasys Ltd.: A leader in 3D printing and additive manufacturing solutions, offering a wide range of technologies and materials for various industries.

-

3D Systems Corporation: Provides comprehensive 3D printing solutions, including printers, materials, software, and services, catering to diverse applications.

-

Materialise NV: Specializes in software solutions and 3D printing services, enabling businesses to transition to additive manufacturing.

-

EOS GmbH: Focuses on industrial 3D printing of metals and polymers, delivering high-quality solutions for complex applications.

-

GE Additive: A division of General Electric, offering additive manufacturing machines, materials, and engineering consulting services.

Conclusion

The additive manufacturing market is poised for substantial growth, driven by technological advancements, increasing demand for rapid prototyping, and supportive government initiatives.

Latest cutting-edge research from Maximize Market Research is now trending:

Global Heat Exchangers Market https://www.maximizemarketresearch.com/market-report/global-heat-exchangers-market/3346/

Global Conveyor System Market https://www.maximizemarketresearch.com/market-report/global-conveyor-system-market/35730/

Maximize Market Research:

Maximize Market Research is one of the fastest-growing Market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

Contact Information:

MAXIMIZE Market RESEARCH PVT. LTD.

3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

sales@maximizemarketresearch.com