Hypobromous acid (HOBr) is an important chemical compound used in various industrial applications, particularly in disinfection, water treatment, and chemical synthesis. It is a weak acid that forms when bromine dissolves in water and is known for its strong oxidizing properties. Due to these properties, hypobromous acid plays a crucial role in eliminating harmful microorganisms, purifying water, and even in some industrial processes. Establishing a manufacturing plant for hypobromous acid is a promising business venture, with growing demand across several sectors, including healthcare, water treatment, and agriculture. However, setting up such a facility requires in-depth knowledge of chemical processes, stringent safety standards, and robust operational planning to ensure the production of high-quality, consistent products.

Market Demand and Applications

Hypobromous acid has a wide array of uses in multiple industries. One of the primary applications is in water treatment, where it acts as a disinfectant, helping to eliminate bacteria, viruses, and other pathogens. Its strong oxidizing properties make it highly effective in killing microorganisms in drinking water, swimming pools, and industrial wastewater. Because of its effectiveness as a disinfectant, it is often preferred over chlorine in certain situations, especially where chlorine's byproducts may be undesirable.

In agriculture, hypobromous acid is used for disinfection purposes in both irrigation systems and seed treatments. It helps control the spread of diseases and pathogens in crops, ensuring healthier yields. Additionally, hypobromous acid is also used in the production of bleach and other chemicals, where its oxidizing power is harnessed to create essential compounds for industrial applications.

The demand for hypobromous acid is also supported by the increasing focus on water sanitation, public health, and environmental safety. As regulations around water quality become stricter globally, industries are looking for more effective, eco-friendly alternatives to traditional disinfectants like chlorine. Hypobromous acid, with its reduced formation of harmful by-products, is gaining traction in such applications.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/hypobromous-acid-manufacturing-plant-project-report/requestsample

Key Considerations for the Hypobromous Acid Manufacturing Plant

Establishing a manufacturing plant for hypobromous acid requires careful planning and consideration of various factors, including raw material sourcing, safety protocols, production processes, and regulatory compliance. Below are the critical aspects of setting up a successful hypobromous acid manufacturing facility.

1. Raw Material Sourcing

The production of hypobromous acid involves the dissolution of bromine in water, typically under controlled conditions. Bromine, the primary raw material, must be sourced from reliable suppliers who adhere to quality standards. The price and availability of bromine can fluctuate depending on global supply and demand, so securing a consistent, cost-effective source is crucial for maintaining production stability.

In addition to bromine, the plant will also require high-quality water and certain stabilizing agents to ensure the efficient and safe formation of hypobromous acid. Proper handling and storage of raw materials are essential, as both bromine and hypobromous acid can be hazardous if mishandled.

2. Manufacturing Process

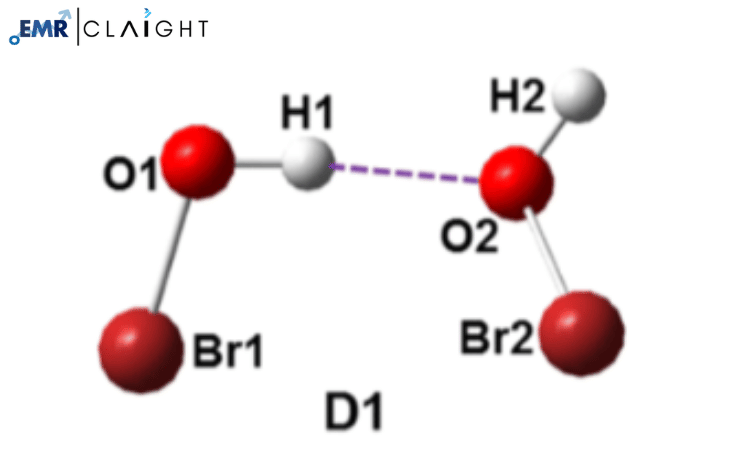

The manufacturing process for hypobromous acid typically involves dissolving bromine in water under controlled conditions. This can be done by introducing bromine gas into water or using sodium bromide solutions to react with chlorine to generate bromine. The resulting mixture then forms hypobromous acid.

Once the hypobromous acid is produced, it must be carefully controlled to ensure the correct concentration and purity. The plant will require equipment for mixing, filtering, and storing the acid under specific conditions. These steps are essential to maintaining consistent quality, as hypobromous acid can degrade over time if not properly stabilized.

Moreover, automation plays a key role in the manufacturing process. Modern plants often incorporate automated systems for monitoring and controlling the production process. This ensures the acid is produced consistently and safely, with minimal human intervention.

3. Safety and Hazardous Material Handling

Given that bromine and hypobromous acid are both highly reactive and can be hazardous, safety measures are critical in the manufacturing process. The plant must be equipped with appropriate safety systems, such as fume hoods, containment systems, and proper ventilation to protect workers from harmful vapours and exposure.

Protective equipment such as gloves, goggles, and face shields should be mandatory for all employees working in the production area. Additionally, emergency response protocols must be in place to handle potential spills, leaks, or accidents involving hazardous chemicals. Proper training in handling hazardous materials is essential for all personnel involved in the manufacturing process.

The plant must also comply with local and international safety regulations, such as Occupational Safety and Health Administration (OSHA) guidelines and Environmental Protection Agency (EPA) standards. These regulations ensure that the plant operates safely and minimizes its environmental impact.

4. Environmental Considerations

Environmental sustainability is a growing concern in industrial production. Hypobromous acid manufacturing plants must take steps to minimize their environmental footprint by ensuring proper waste management and reducing harmful emissions. Efforts can be made to recycle water used in the production process, minimize the release of bromine or other hazardous chemicals into the environment, and reduce energy consumption.

The plant should be designed to meet environmental regulations for air and water quality, ensuring that waste products are treated and disposed of in an environmentally responsible manner. Regular audits and inspections are essential to ensure compliance with environmental standards and to implement continuous improvement initiatives.

5. Quality Control and Consistency

Quality control is crucial in the production of hypobromous acid. The product must meet specific purity standards to be effective as a disinfectant or in other industrial applications. Consistency in product quality is also important to ensure that customers receive a reliable product with predictable performance.

The plant should implement a robust quality control system that includes routine testing of the hypobromous acid’s concentration, pH level, and stability. Sampling procedures should be in place to detect any deviations in product quality early in the production process. By adhering to strict quality control measures, the plant can ensure that the final product meets industry standards and customer requirements.

6. Packaging and Storage

Hypobromous acid is typically sold in liquid form and must be carefully packaged to ensure it is safely transported and stored. The packaging should be resistant to corrosion and designed to prevent leaks or spills. Typically, packaging materials like high-density polyethylene (HDPE) or glass containers are used, as they are resistant to the corrosive properties of hypobromous acid.

In addition to packaging, proper storage conditions must be ensured to maintain the stability of the product. Hypobromous acid should be stored in cool, dry environments away from direct sunlight or heat sources. The storage area should be clearly marked with safety warnings and include the necessary spill containment equipment.

7. Regulatory Compliance and Market Demand

A hypobromous acid manufacturing plant must adhere to various regulatory standards, including those set by local governments, environmental agencies, and health organisations. These regulations govern not only the production processes but also the sale and distribution of the product.

Understanding market demand is also essential for ensuring that the production plant operates efficiently. The plant should be designed with scalability in mind, allowing for future growth in response to increasing demand in water treatment, agriculture, and other industries. Manufacturers should keep abreast of changes in environmental regulations and technological advancements that may impact the demand for hypobromous acid.

8. Distribution and Logistics

Once the hypobromous acid is manufactured and packaged, it needs to be distributed efficiently to customers. The logistics for transporting hazardous chemicals must comply with strict safety standards, including proper labelling, transportation containers, and safety protocols for handling during transit.

Establishing a reliable distribution network is essential to ensure timely delivery to customers. Manufacturers may need to partner with local and international distributors to expand their reach. Establishing strong relationships with key stakeholders in various industries, including water treatment plants and agricultural suppliers, can help expand the customer base and ensure long-term business success.

Expanding the Product Portfolio

As the hypobromous acid manufacturing plant becomes operational, there may be opportunities to diversify the product portfolio. For example, manufacturers can explore producing other bromine-based compounds, such as sodium bromide or calcium hypobromite, which are used in water treatment and industrial applications. Expanding the product range can help businesses tap into new markets and meet the varying needs of different industries.

Further research and development into more sustainable production methods, such as using renewable energy or reducing waste, can also provide a competitive edge. By continuously innovating and diversifying, a hypobromous acid manufacturing plant can establish itself as a key player in the chemical production industry.